The pH level will always remain unchanged thanks to a modern infrared sensor, while the temperature accuracy will be taken care of by direct heating technology and the VentiFlow™ ventilation system. Isocide™ coating prevents any development of bacteria on the surface of the device, and the rounded corners of the chamber will simplify the process of cleaning the equipment. The complex of ROBUST™ decontamination procedures, for its part, guarantees sterility and reliability of the obtained results. In particular, the range of additional options and accessories will make it possible to supplement the equipment with the necessary elements for even better simulation of conditions.

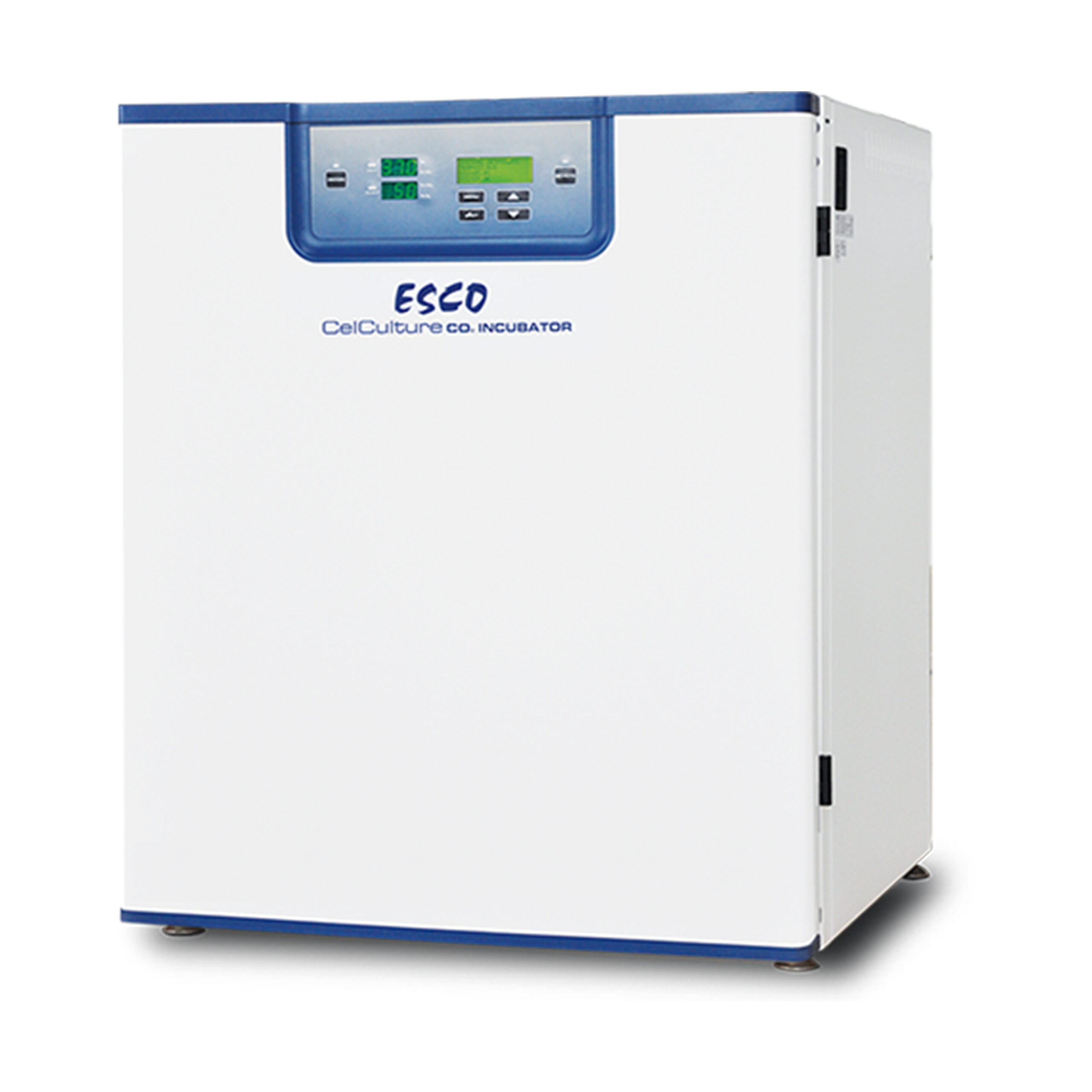

| Manufacturer | ESCO |

|---|---|

| Type of equipment | CO2 incubators |

| Series | CelCulture® |

| Temperature range, ⁰С | 25… 50(60)°С |

| Oxygen control | Yes |

| CO2 sensor with the possibility of sterilization | Yes |

| Стерилізація | +90 |

| Display | Fluorescent Digital |

| ULPA filter | Yes |

| Working volume of the camera |

Additional information

Important advantages of the CelCulture® CCL-T series:

|

|

|

|

|

|

|

|

|

|

|

|

|

Materials for download

The pH level will always remain unchanged thanks to a modern infrared sensor, while the temperature accuracy will be taken care of by direct heating technology and the VentiFlow™ ventilation system. Isocide™ coating prevents any development of bacteria on the surface of the device, and the rounded corners of the chamber will simplify the process of cleaning the equipment. The complex of ROBUST™ decontamination procedures, for its part, guarantees sterility and reliability of the obtained results. In particular, the range of additional options and accessories will make it possible to supplement the equipment with the necessary elements for even better simulation of conditions.

| Manufacturer | ESCO |

|---|---|

| Type of equipment | CO2 incubators |

| Series | CelCulture® |

| Temperature range, ⁰С | 25… 50(60)°С |

| Oxygen control | Yes |

| CO2 sensor with the possibility of sterilization | Yes |

| Стерилізація | +90 |

| Display | Fluorescent Digital |

| ULPA filter | Yes |

| Working volume of the camera |

Additional information

Important advantages of the CelCulture® CCL-T series:

|

|

|

|

|

|

|

|

|

|

|

|

|